| Client | City of Zurich |

| General planning | Boltshauser Architekten |

| Architecture | Boltshauser Architekten |

| Planning | since 2020 |

| Status | In planning |

In the Oerlikon district of Zurich, a new building is being constructed to replace the aging Oerlikon indoor swimming pool, the artificial ice rink, and the Neudorf field sports complex. The new sports center, which is unique in Switzerland in terms of its size, has a compact form that complements the nearby, block-like sports and event facilities. It comprises three main areas: indoor ice rinks; swimming pools for competition, diving, and leisure; and an outdoor pool. The separate and clearly structured areas are accessed from a common lobby and a “rue intérieure,” or inner street. The design of the 26-meter-high building focuses on climate-friendly construction, in terms of both architecture and building technology. The facility is designed to be as energy self-sufficient as possible by using the waste heat from the ice production process—which is temporarily stored in thermal storage tanks housed within the externally visible towers. The electrical energy required for this is provided by photovoltaic panels integrated into the exterior as a cornice for the compactly shaped building. This energy concept covers most of the of the total heating demand.

The striking, 26-meter-high heat storage tanks are built as earthen cylinders that also support the roof structure. Earthen elements are typically used only to provide thermal mass and rarely also perform a structural role. Here, the stability and load-bearing capacity of loam with trass lime offers a potential that is exploited by using threaded rods to prestress the components formed from it.

The timber construction is noteworthy. The roof beams, which span up to 45 meters and must not deflect more than 5 millimeters in the areas above the ice rinks due to the risk of ponding, are prestressed to achieve a load-bearing capacity and durability never before achieved in timber construction. The beams’ timber lamellas are milled in a parabolic shape in order to receive the tendon sheaths. Once the beam components have been glued together, the prestressing strands are inserted and grouted to create a composite effect—an established method borrowed from reinforced concrete construction that provides a structurally efficient moment arm as an internal bond and protects the cable from fire and corrosion. By combining tradition and innovation, there is no need for new anchors and presses—proven techniques are used. The ends of the beams, which hold the prestressing anchors, are made of concrete to distribute the expansion forces evenly over a short distance and transfer them to the timber beam. Although concrete has a large CO2 footprint, its malleability allows for efficient load transfer. The hard material is used where necessary, otherwise sustainable wood is used. The selective choice of materials makes optimum use of advantageous properties and, thanks to the structurally rational load-bearing system with prestressing, the result is a structure with a good-natured load-bearing behavior that facilitates any potential need for load redistribution. This combination ensures high load capacity and prevents the risk of brittle failure. Theoretical research and large-scale practical tests at ETH Zurich and FHNW Muttenz confirm the efficiency and feasibility of this construction method.

The project is a prototype of the symbiosis between ecology, structure, and architecture. The insights obtained pave the way for future construction projects with robust and rigid timber structures with large spans of around 15 meters or more. They are a valuable source of inspiration for a wood Baukultur of high quality.

Competition (second phase), main girder in prestressed glulam, May 2021

studio blomen, Zürich

Competition (second phase), main girder in prestressed glulam, May 2021

studio blomen, Zürich

Competition (second phase), main girder in prestressed glulam, May 2021

studio blomen, Zürich

Competition (second phase), main girder in prestressed glulam, May 2021

studio blomen, Zürich

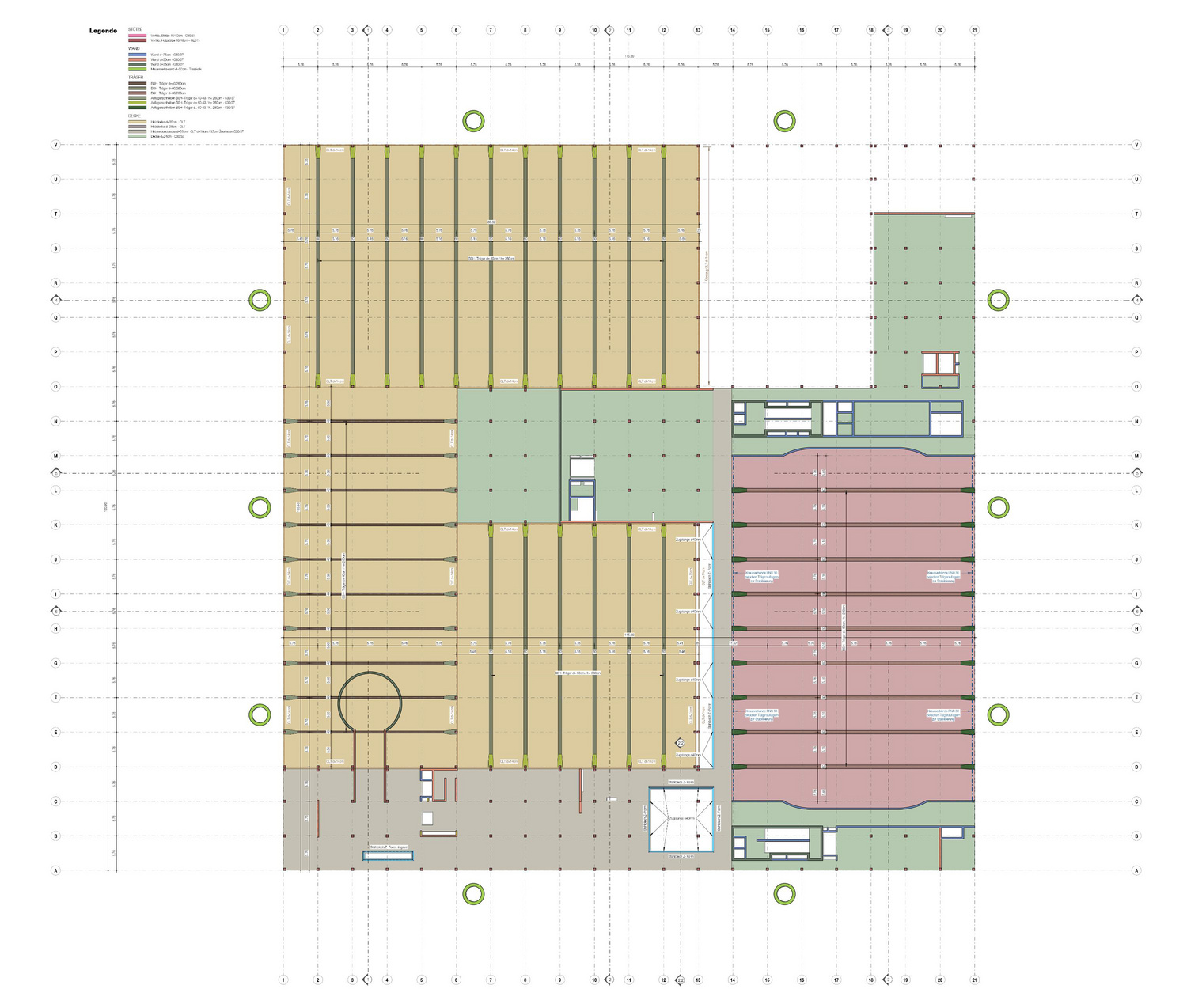

Green: Reinforced concrete components; Brown: timber-concrete composite; red: prestressed timber beams in the stacked ice rink area

Schnetzer Puskas Ingenieure

Green: Reinforced concrete components; Brown: timber-concrete composite; red: prestressed timber beams in the stacked ice rink area

Schnetzer Puskas Ingenieure

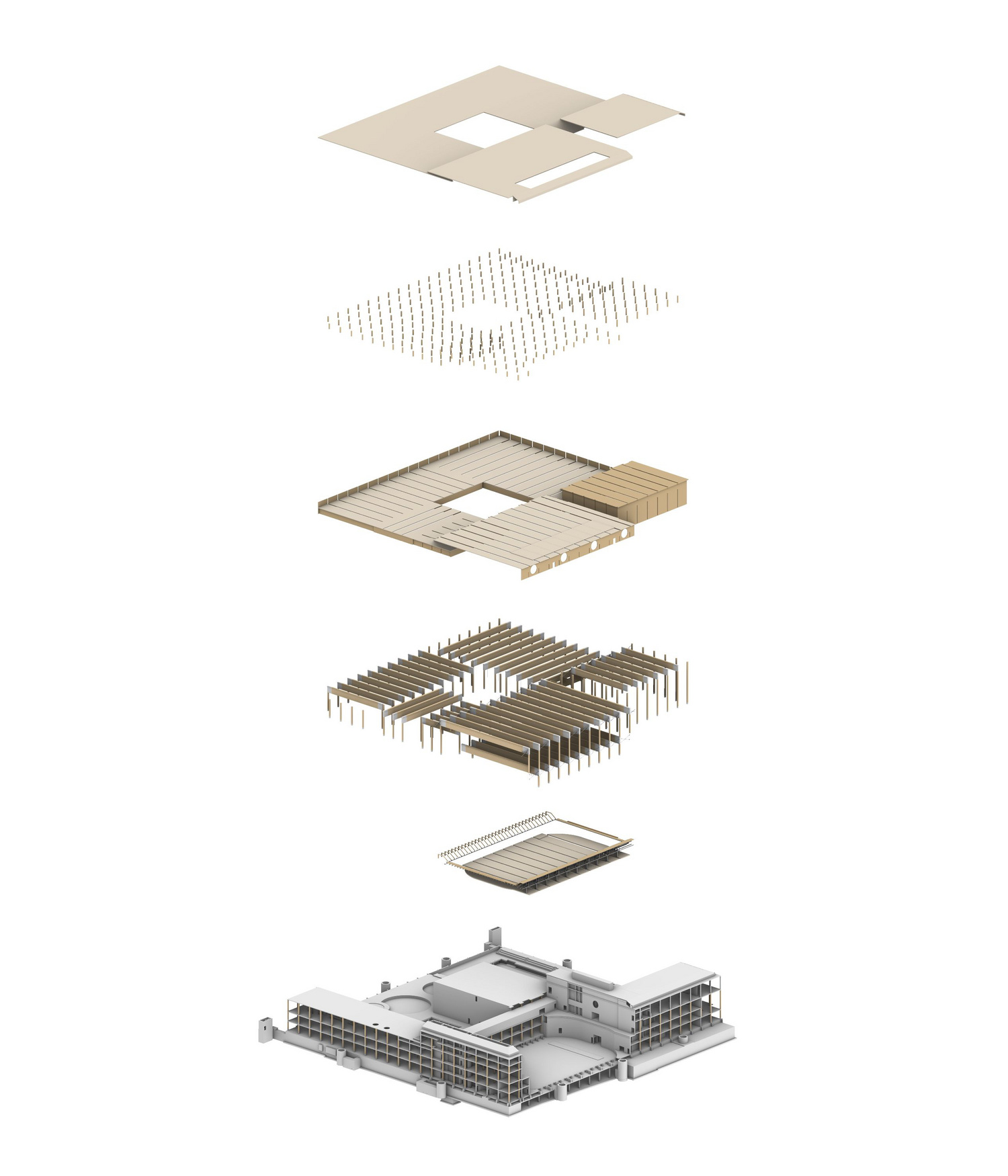

Individual structural components (from bottom to top): reinforced concrete components, prestressed timber girders, above: Roof structure in cross laminated timber construction

Schnetzer Puskas Ingenieure

Individual structural components (from bottom to top): reinforced concrete components, prestressed timber girders, above: Roof structure in cross laminated timber construction

Schnetzer Puskas Ingenieure

View of the sports center and outdoor pool (visualization)

studio blomen, Zürich

View of the sports center and outdoor pool (visualization)

studio blomen, Zürich

| Client | City of Zurich |

| General planning | Boltshauser Architekten |

| Architecture | Boltshauser Architekten |

| Planning | since 2020 |

| Status | In planning |