| Client | F. Hoffmann-La Roche AG |

| Architecture | Herzog & de Meuron Ltd. |

| Structural Engineering | INGE Proplaning Ingenieure / Schnetzer Puskas Ingenieure AG |

| Planning | 2015-2017 |

| Realization | 2017-2020 |

| Status | Built |

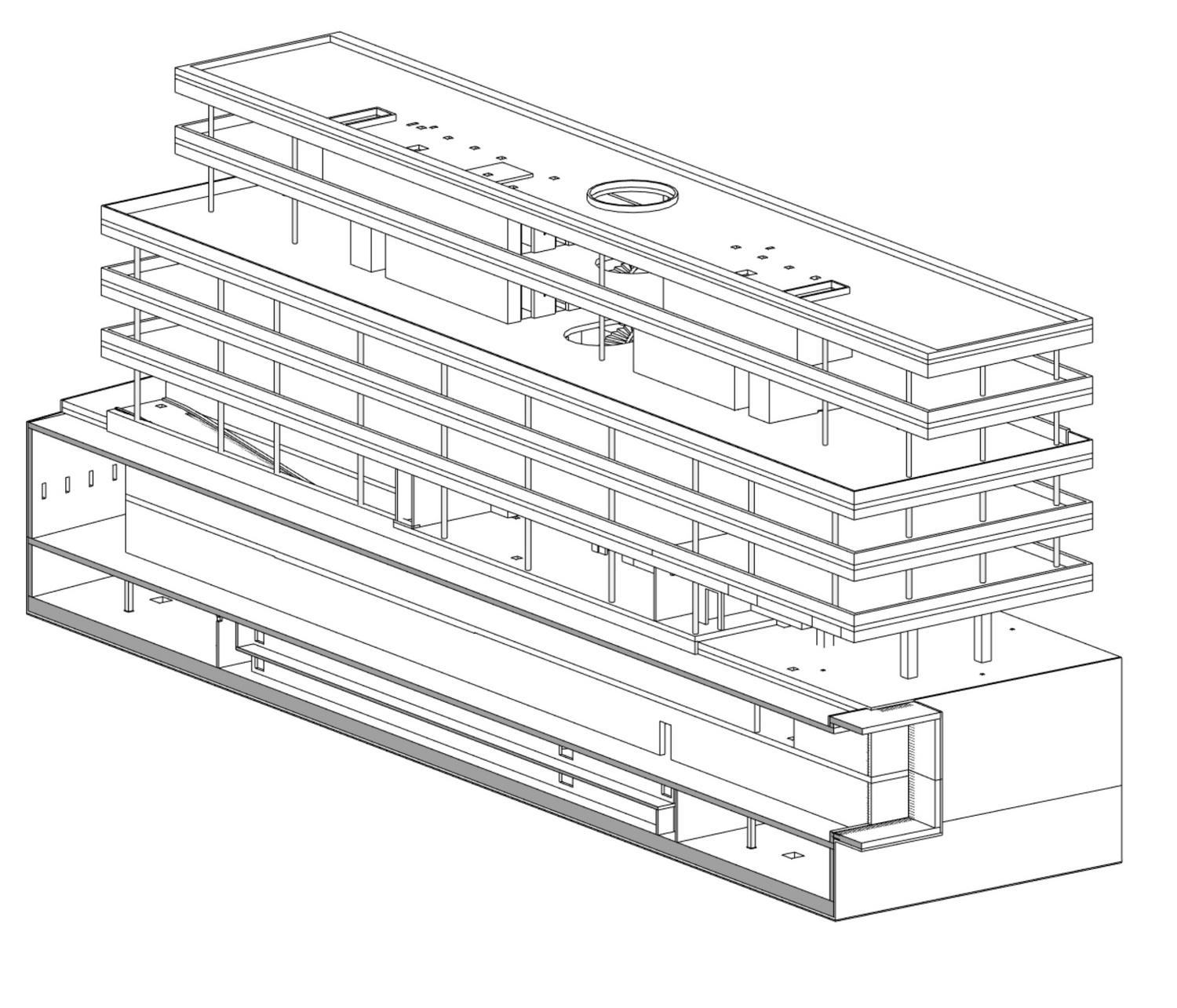

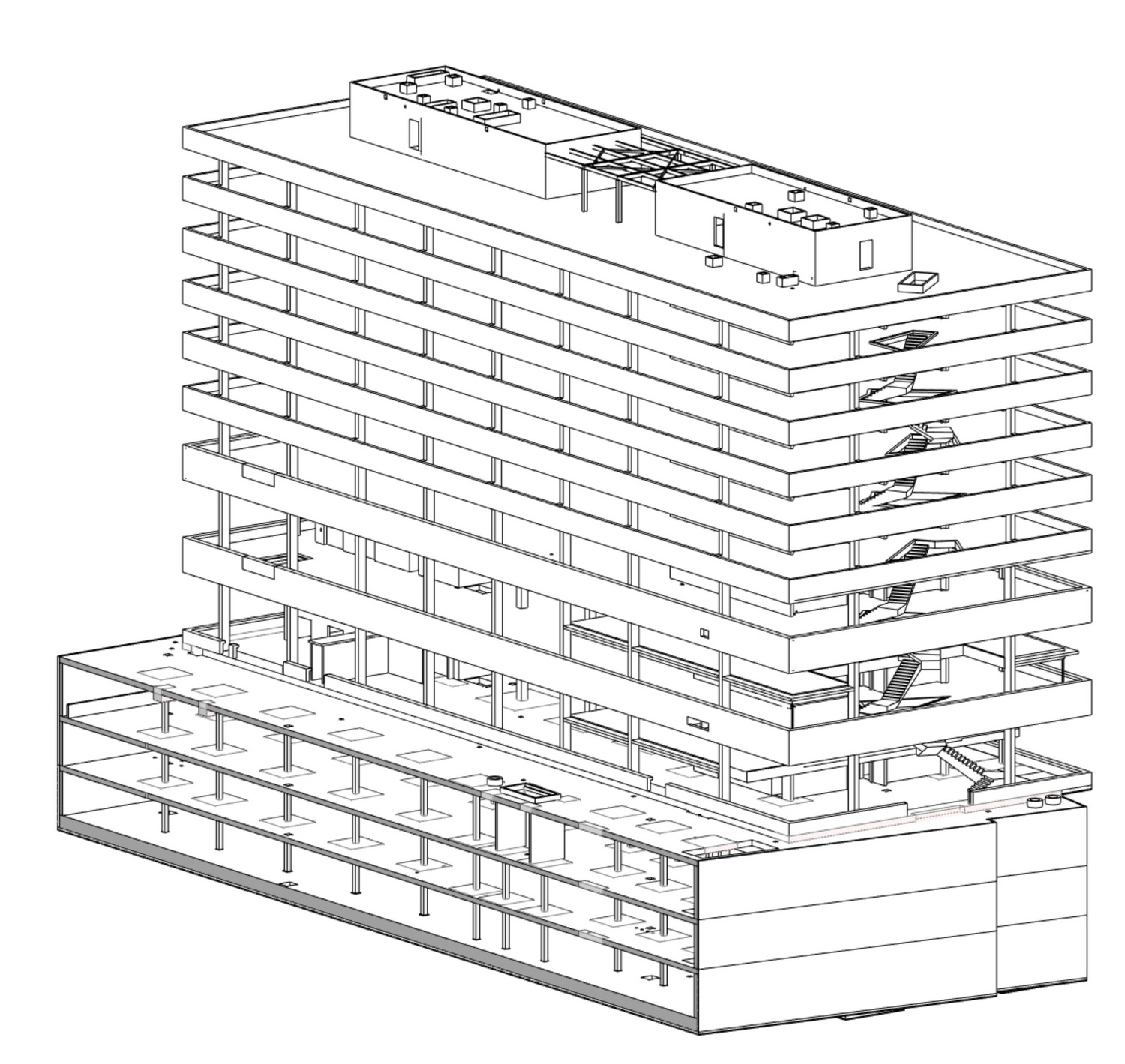

Biotech giant Roche has expanded its Basel site with the addition of Buildings 08 and 11 to house a new service and support center. The project comprises two structures: the eight-story Building 08 and Building 11, which has five floors. Both are founded on a shared three-level basement structure sunk into the ground. These underground floors are used for parking, plant rooms and various storage facilities. Above ground, Building 08 houses workshops and office space, Building 11 a wellness and fitness area, a club and shops.

Building 11 was designed as a reinforced-steel skeleton structure with reinforcing cores. Above the ground floor, vertical loads are transferred directly down to the foundations via the cores, the facade supports and a double row of supports within the building. The only exception is the area of the ‘Roche Club’ situated above thew ground floor, where the facade support loads are transferred via a prestressed edge beam to two prestressed main beams that ultimately discharge the loads into four columns inside the building. Lateral stabilization is provided by the access cores inside the building, which are tied into the basement frame.

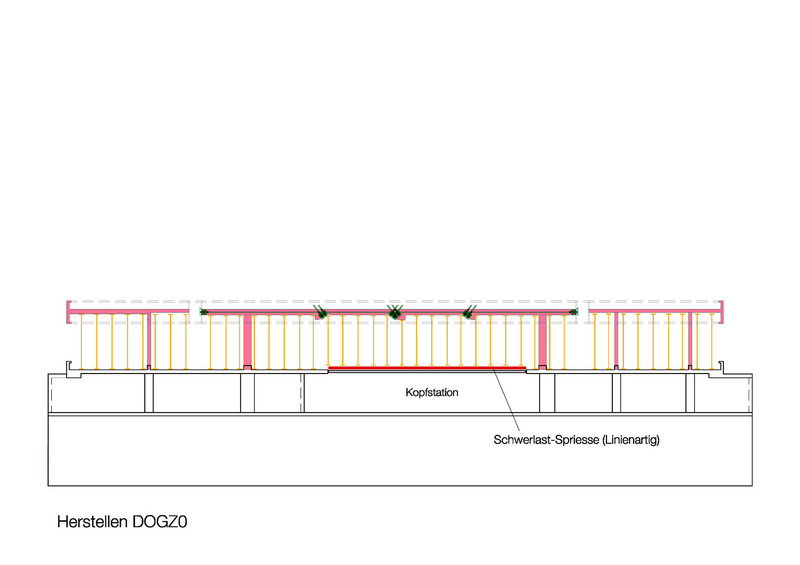

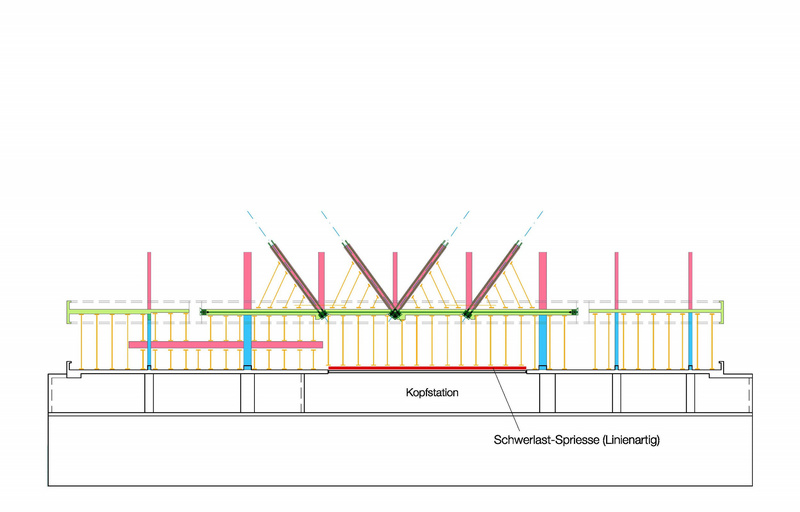

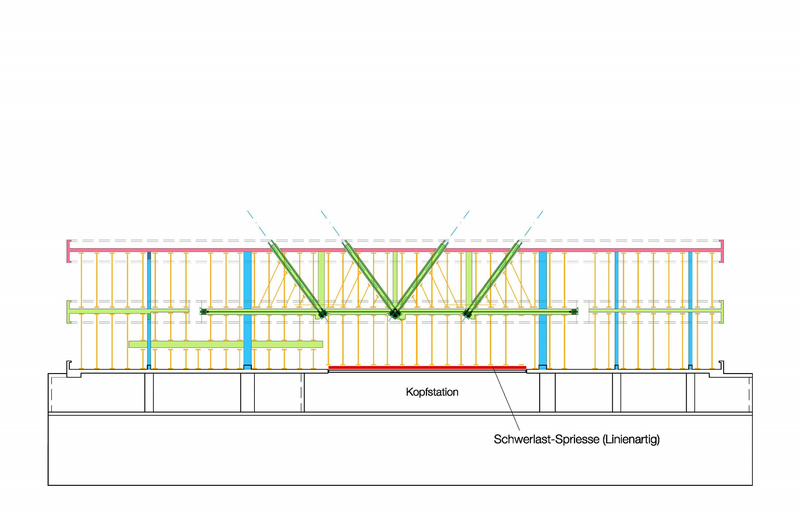

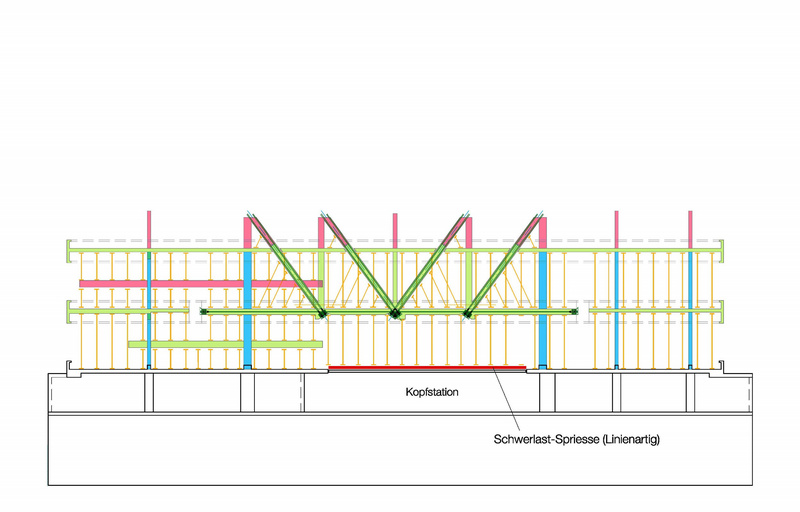

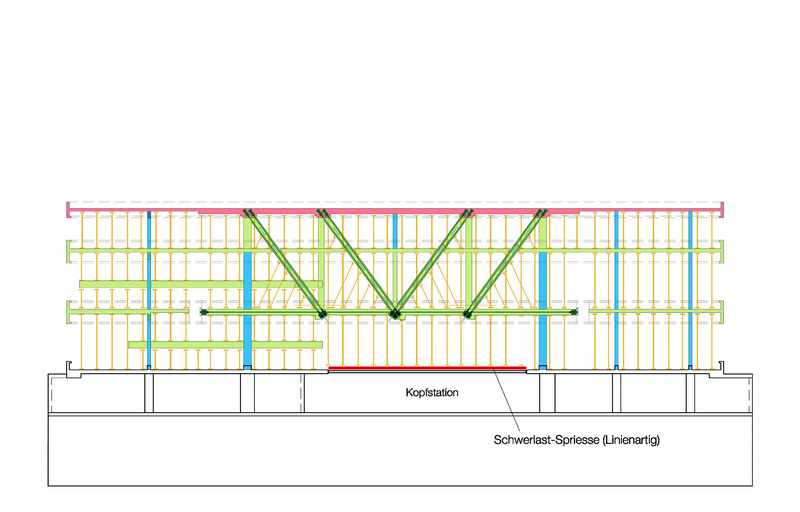

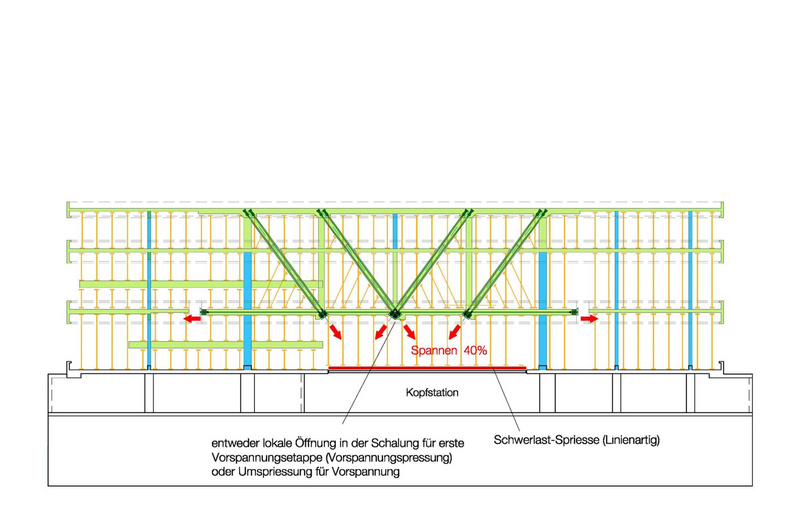

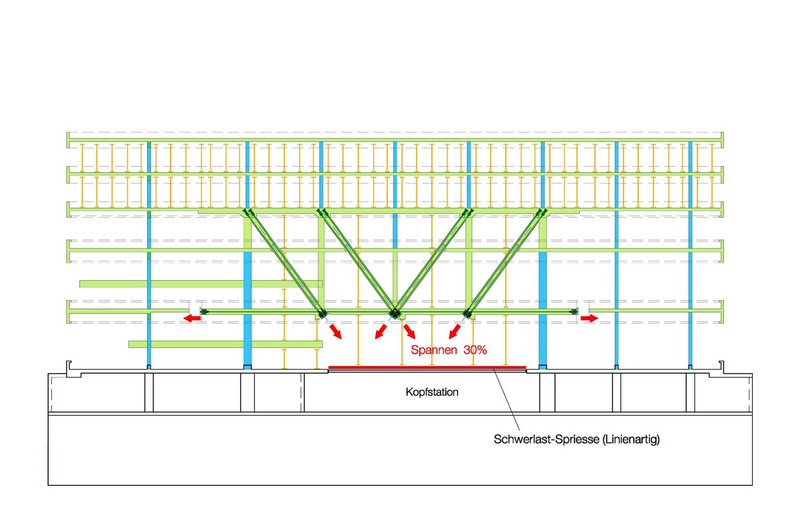

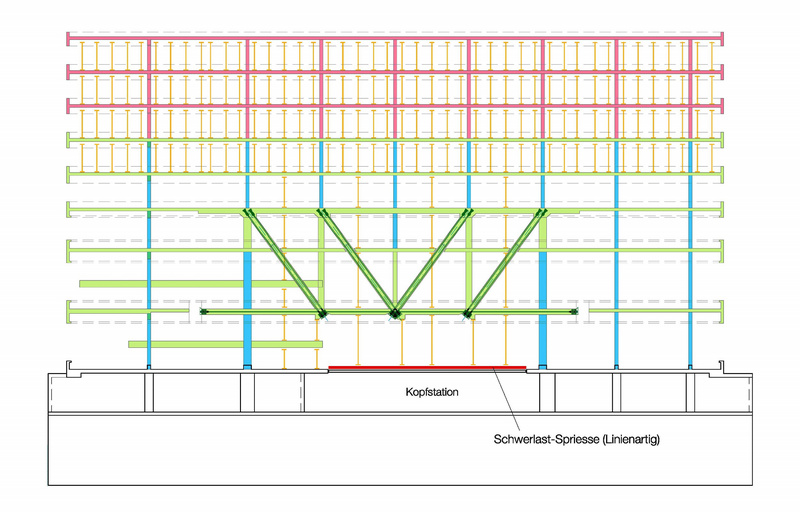

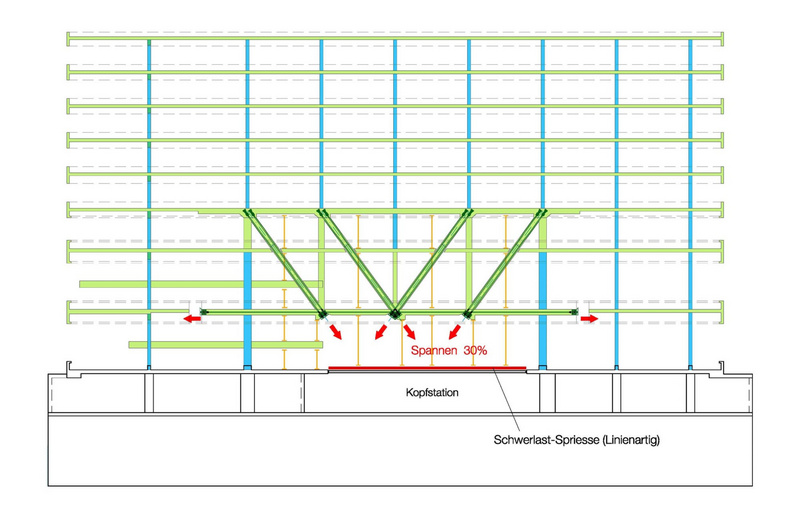

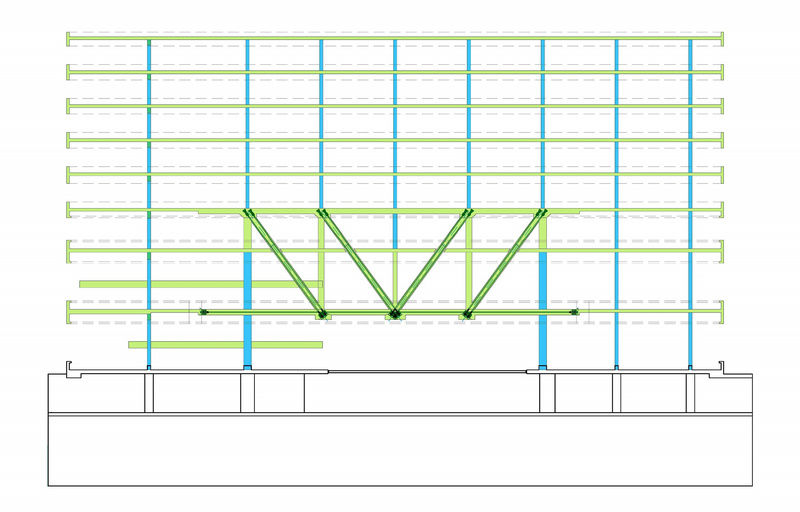

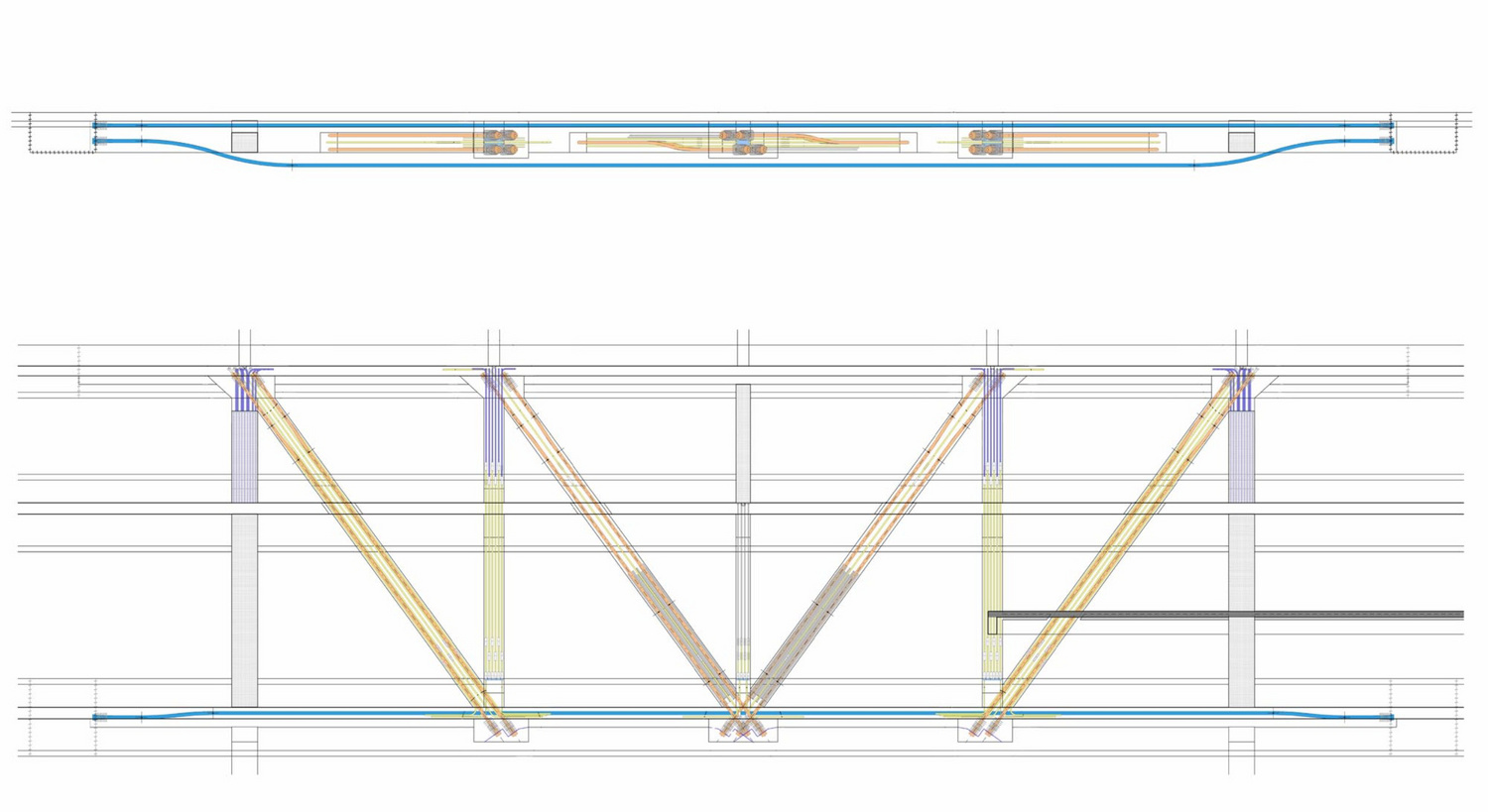

The structural system employed in Building 08 was dictated by the presence of the existing cable headend. This underground headend, located on level -1 within the perimeter of Building 08, was overbuilt with a bridge-like structure. The floor loads on the first and second floors are absorbed at facade level by a double-story reinforced concrete truss that spans slightly over 35 meters. Both webs and bottom chord are prestressed to take up the majority of the load from the eight floors above the headend. In order to control deformation of the slabs and so of the double-story truss, and to match this deformation to that occurring in the areas of the building adjacent to the headend zone, the webs and bottom chord were prestressed in stages as the building grew. As each new floor was added, the imposed load increased while the compression force in the webs, for example, decreased. In addition, the slabs, which have a span width of 10 x 8.70 meters and measure 30 to 35 cm, are dimensioned to provide a load capacity of up to 1.5 t/m2. Only some of the floor loads rest directly on the prefabricated supports since here, too, the slabs are surrounded by a slab edge beam that reduces slab edge deformation and punching-shear load on the supports.

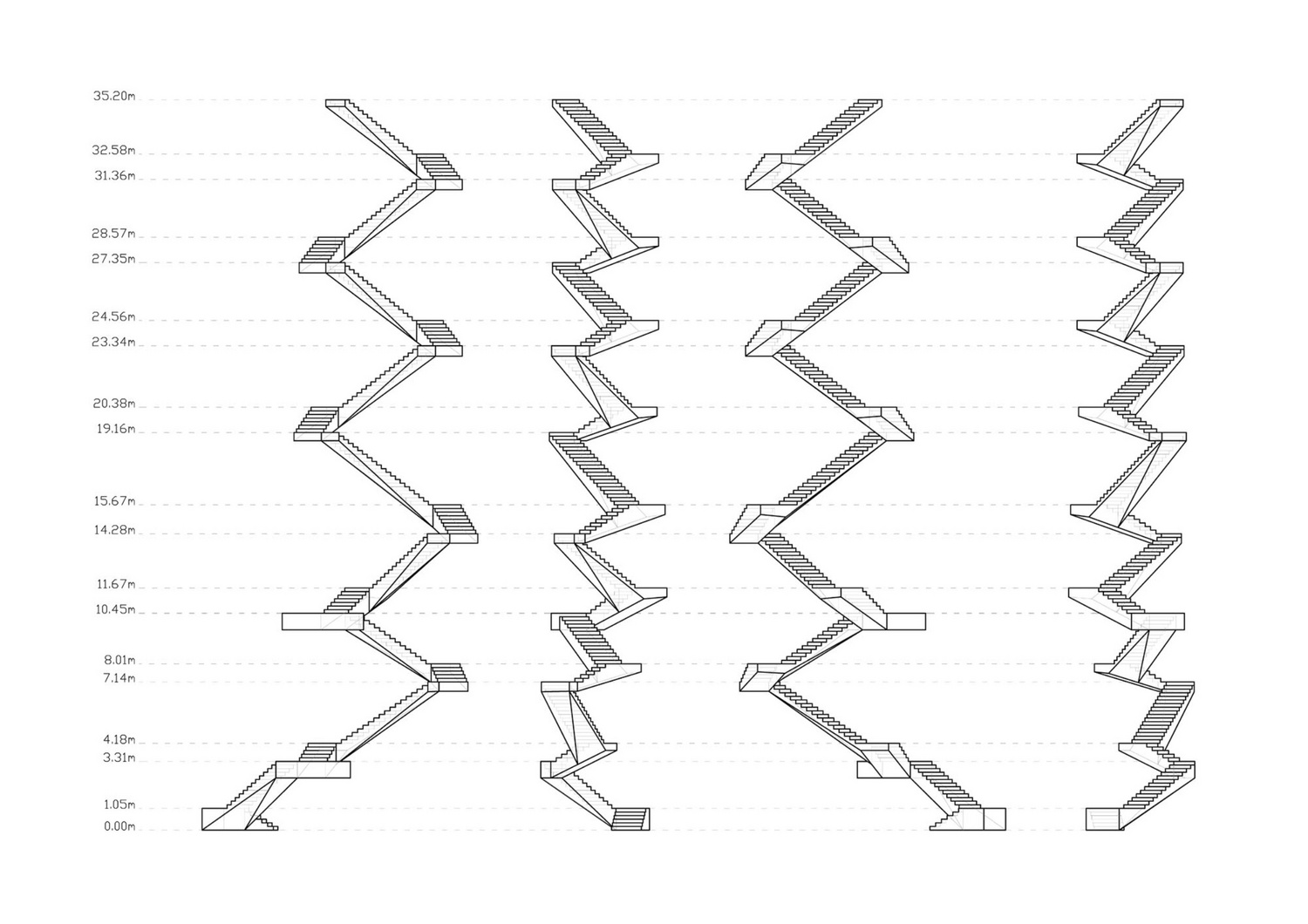

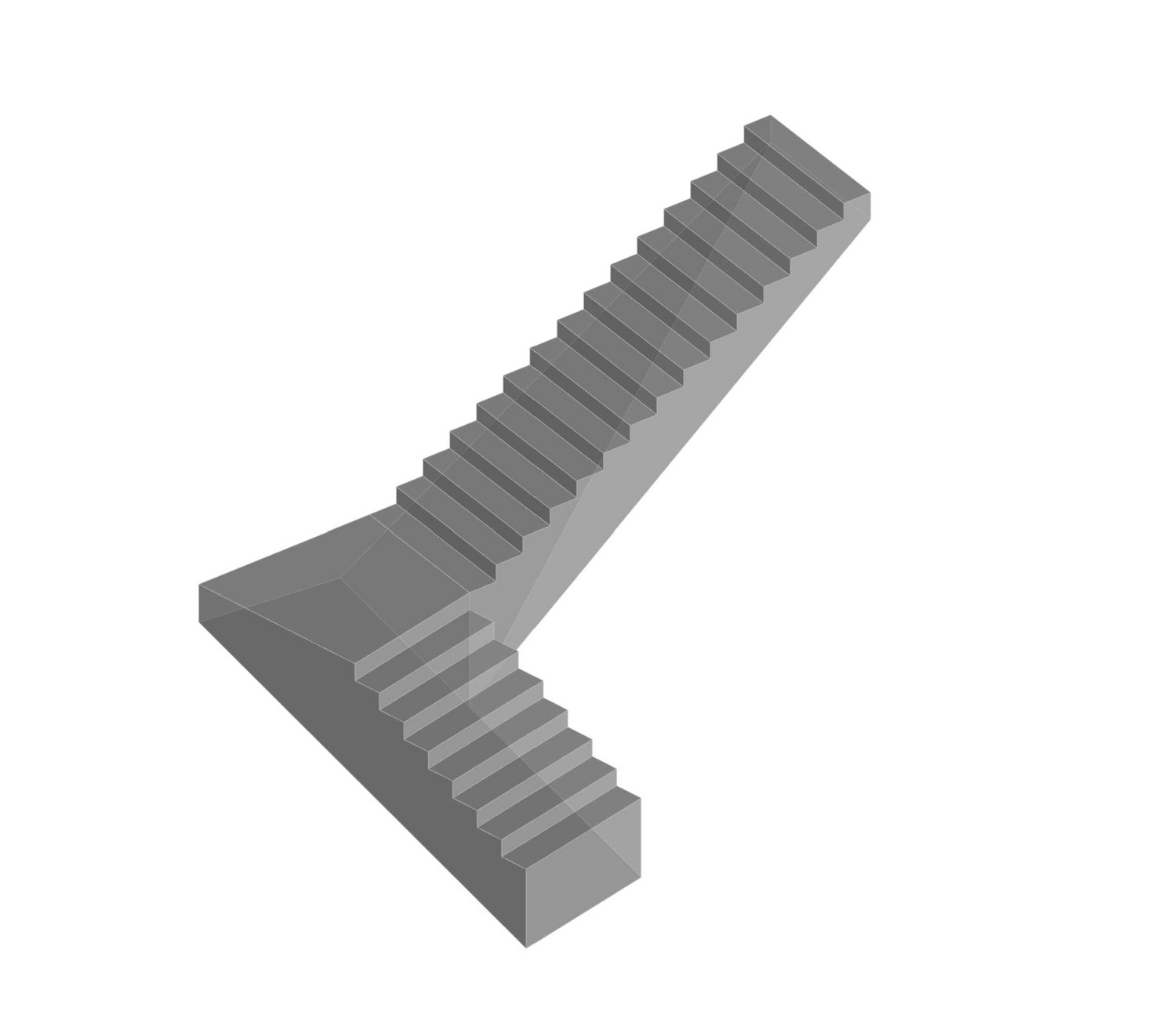

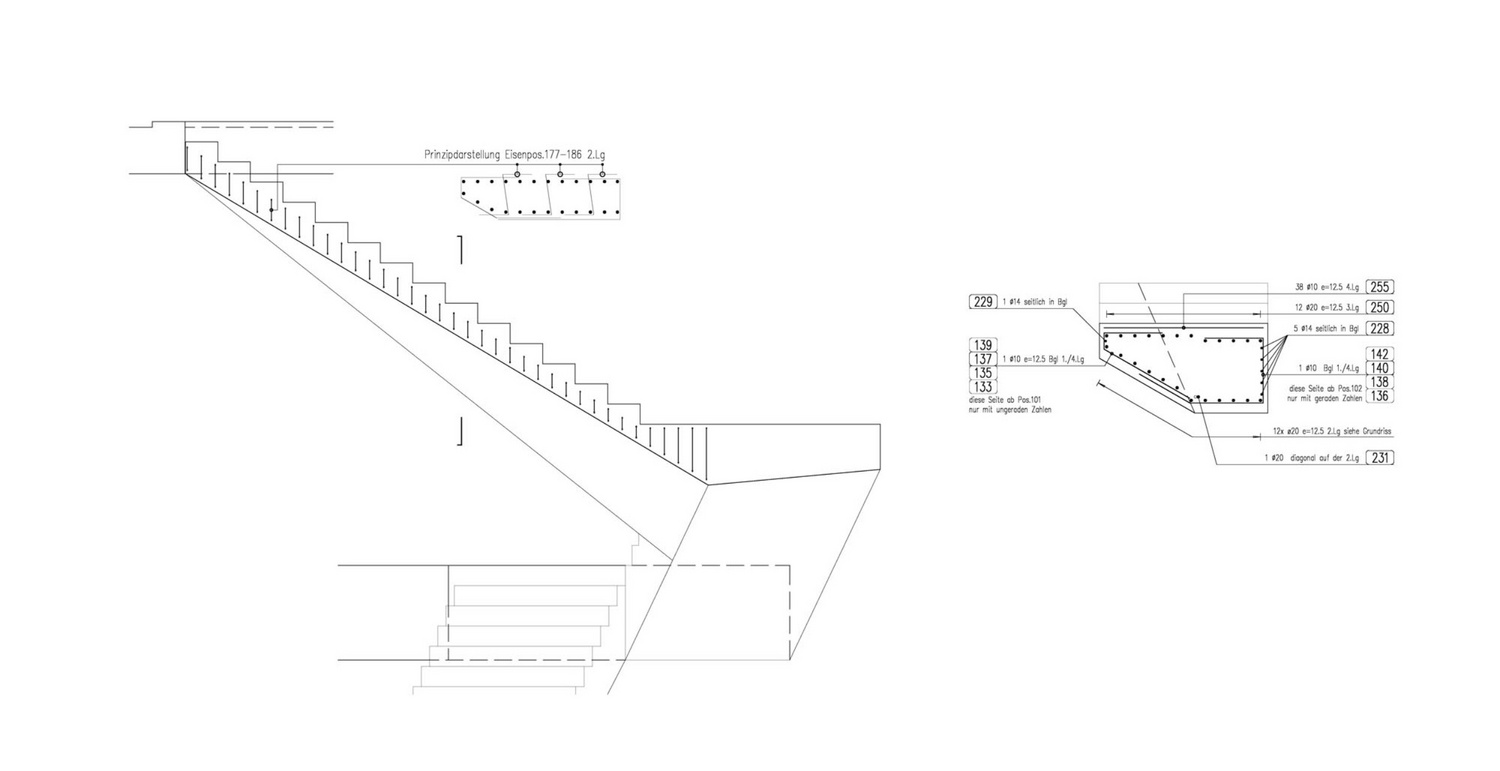

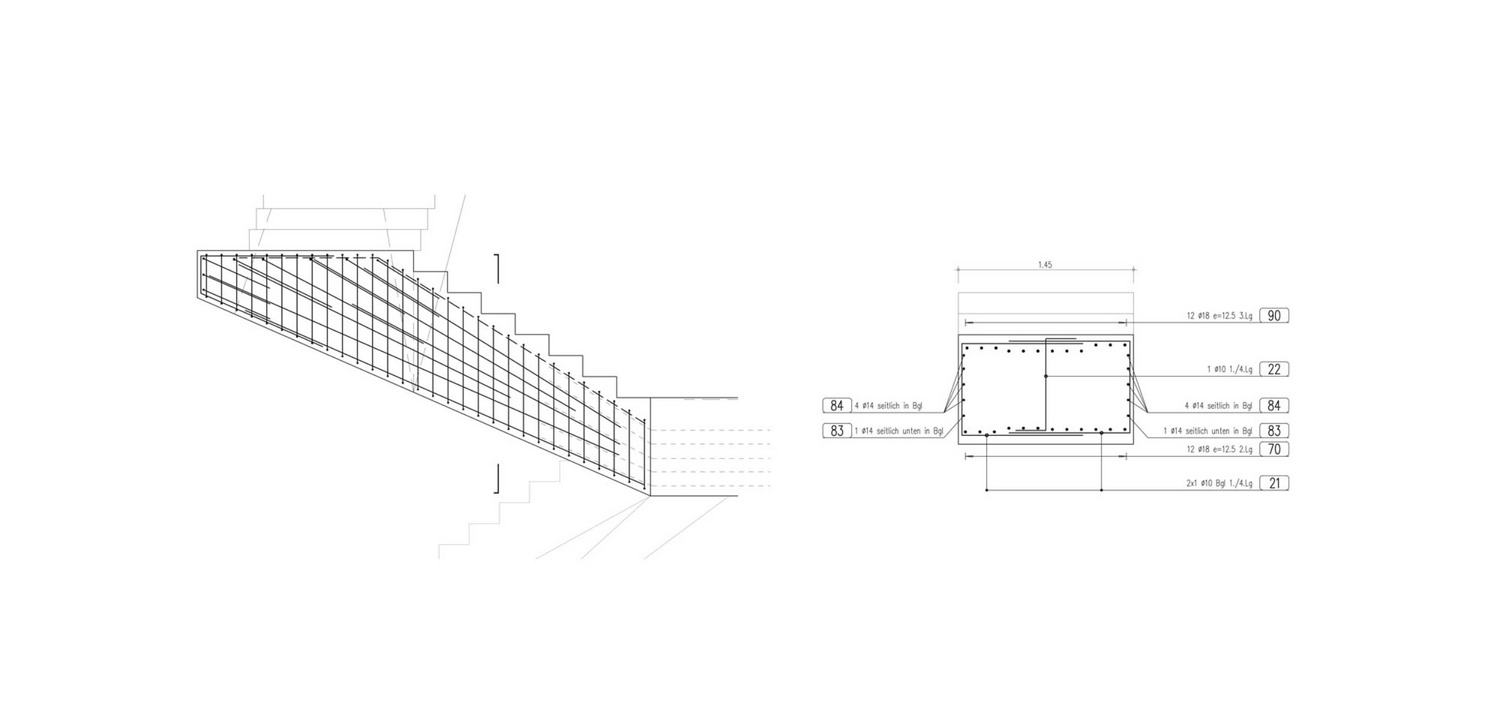

The main staircase presented a major challenge. Connected to the primary load-bearing structure by the slabs alone, it projects from the slab edge by up to 4 meters as far as the inflection point.

Both buildings sit on a flat floor slab with large-diameter bored piles additionally arranged in the region of the cable headend to prevent damage due to settlement. As a result, the zone around the cable headend has a combined bored pile/slab foundation.

Both buildings sit on what is effectively a flat floor slab, though a number of large-diameter bored piles are also arranged in the region of the cable headend to prevent damage due to settlement. As a result, the zone around the cable headend has a combined bored-pile/slab foundation.

The project was planned and implemented in 3D according to the BIM guidelines provided by Roche.

| Client | F. Hoffmann-La Roche AG |

| Architecture | Herzog & de Meuron Ltd. |

| Structural Engineering | INGE Proplaning Ingenieure / Schnetzer Puskas Ingenieure AG |

| Planning | 2015-2017 |

| Realization | 2017-2020 |

| Status | Built |