| Client | Royal Government of Bhutan / Helvetas Swiss Intercooperation |

| Planning | 1998-2000 |

| Realization | 2000-2002 |

| Status | Built |

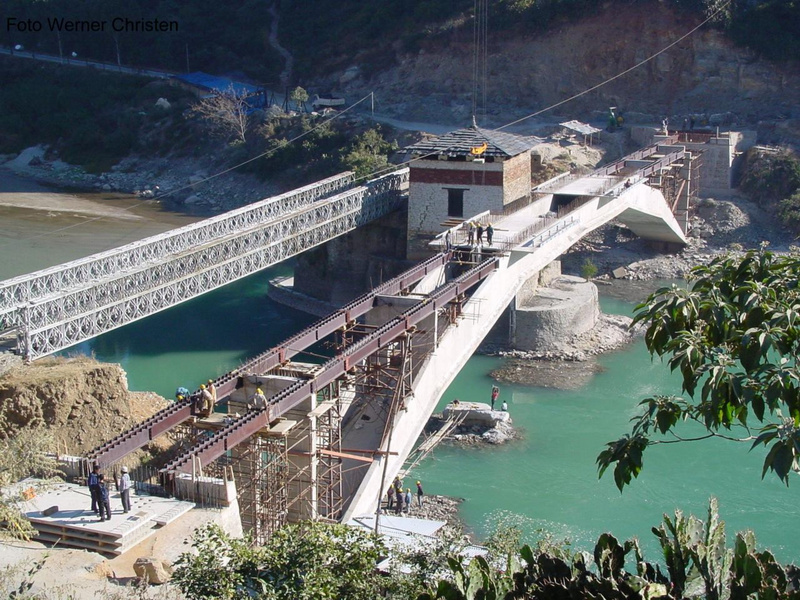

River regimes in Bhutan are characterized by recurrent periods of extreme flooding caused by the annual monsoon rains and run-off from glacial lakes. A key project requirement was therefore to develop a structure with a flow cross-section and foundations able to withstand such flood events.

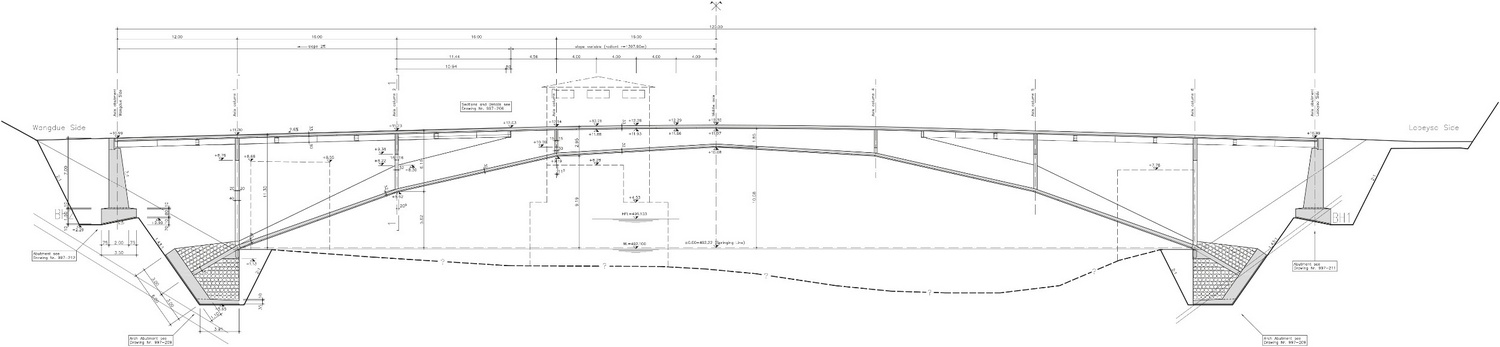

Building the bridge using the limited resources at our disposal locally meant finding an appropriate load-bearing concept. Working with the construction capacities available on the ground, we had to adapt the latest technological findings and operate within local economic limitations. Though the planned location had already been chosen for a traditional wooden bridge more than 200 years earlier, geotechnical constraints at the site and the lack of the plant and equipment necessary to construct pier foundations in the river required a bridge structure with a span of some 100 meters – no mean feat even in technologically advanced Switzerland. An arched bridge with abutment foundations in the exposed bedrock of the valley sides proved the best match for the geotechnical, geometrical and economic conditions. Comparisons with old arched bridges built in Switzerland showed that structures of this type offer a high construction material to labor costs ratio and are therefore extremely economical to build.

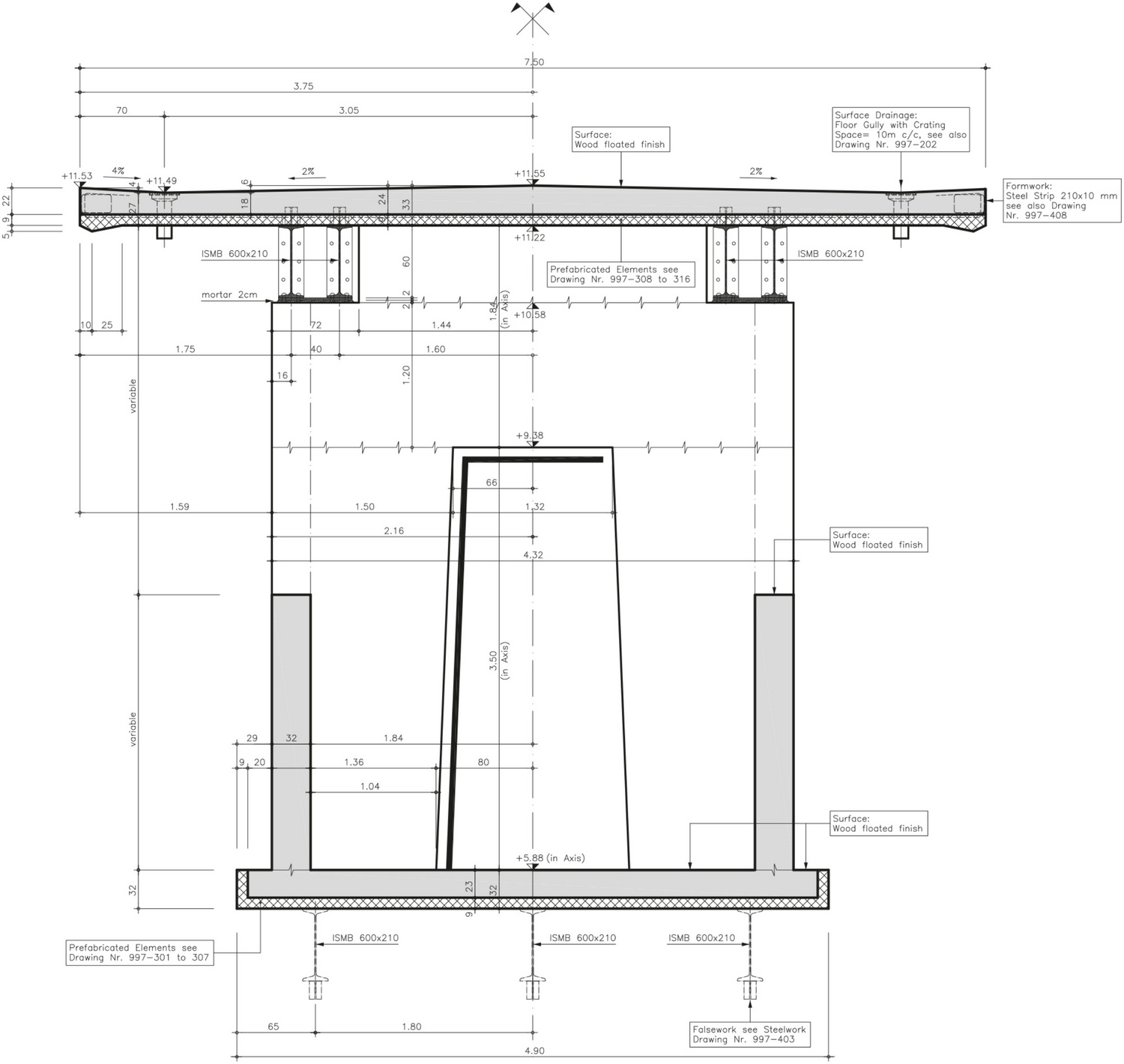

The recurrent monsoon rains and rising water table limited construction time on the riverbed to a period of six months over the winter and both the arch structure – including falsework set on five steel piles – and the abutment foundations had to be completed during this window. To meet the tight construction schedule, the concept chosen for the construction of the arch relied on tried-and-tested methods implemented in conjunction with a modern construction process that would work in Bhutan. The arch and carriageway slabs were partially prefabricated from concrete elements at a small production plant close to the building site and, once set in position, were used as formwork for the concrete topping. The arch ribs were cast in situ. The steel girders for the falsework, on the other hand, were manufactured in Calcutta, then transported to the site. To compensate for the high transport costs, they were designed so that, when the concrete arch was finished, they could be removed and reused as composite girders for the carriageway slab.

Once the falsework had been erected, the arch segments were set in position and the 2cm-thick joints sealed with mortar. As soon as the last piece of the arch – or keystone – was slotted into place, the segments started working together to form a pressure arch, relieving the load on the falsework and freeing up bearing reserves for other loads. It was then time to pour the topping concrete on the arch and cast in the ribs that would stabilize the thin arch. It took a full seven months to achieve this level of stability. Only then were the piers and abutments constructed, the falsework girders dismantled prior to being re-used on the carriageway girders, and the prefabricated carriageway components finally laid. The steel edging to which the larch-wood walkway that now runs the length of the bridge would be fixed was integrated in the topping on the carriageway slab as stop-end formwork.

| Client | Royal Government of Bhutan / Helvetas Swiss Intercooperation |

| Planning | 1998-2000 |

| Realization | 2000-2002 |

| Status | Built |